Warrick Liquid Level Controllers

About our Warrick Liquid Level Controllers

For over 50 years Warrick® Controls have offered dependable no-moving-parts control and monitoring of conductive liquids. Now as part of the Gems™ Sensors family, Warrick® conductivity controls continue to offer reliability, process automation, labor savings, flexibility and operator safety at economical cost. The concept is simple: take advantage of a liquid’s conductive properties to complete a circuit and cause a control relay to actuate. Use of permanently-mounted stationary electrodes gives the user precise accuracy, repeatability and no-moving-parts reliability. This simple concept has led to the development of a complete line of conductivity-based liquid level detectors, water level detectors, and control units and electrode fittings shown here. For OEM’s we also have the capability to custom configure liquid level control units and electrode fittings to meet your specific application requirements.

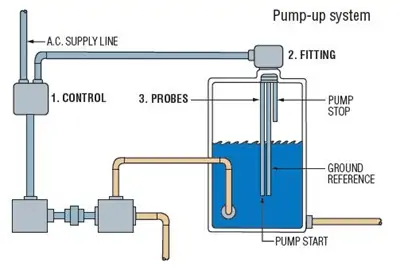

System Components

- The liquid level control unit is an electrical device with contacts that open and close in response to liquid levels sensed by the probes. Because it is wired directly to the power source and to the sensing source, it can send signals that activate or de-activate solenoids, pumps, alarms or pressure switch devices. Warrick® controls are available in many different designs and sensitivity ratings for a wide range of application requirements.

- The fitting is a housing that holds the probes (or floats), insulates them from the vessel, and provides a means of connection to the control. Warrick® fittings are available for single-probe or multi-probe applications, for mounting to vessels in a variety of ways, and in open or pressure tight styles.

- The probe is a sensor that extends downward from the fitting, with the tip positioned precisely at the level where the control should be activated. Warrick® probes are available in a variety of materials to suit different liquids and a variety of lengths to fit different depth requirements.

The liquid level control system shown here is designed for “pump up” application. The pump will start refilling the vessel when the liquid reaches the lower probe tip, then stop refilling the vessel when the liquid reaches the higher probe tip.

Frequently Asked Questions

- How does a Warrick Liquid Level Controller work?

-

Warrick Liquid Level Controllers monitor the level of conductive liquids. They take advantage of this liquid’s conductive properties by completing a full circuit and causing a control relay to actuate. The addition of stationary electrodes then gives the user complete accuracy and the ability to control the liquid level.

- What are the benefits of using a Warrick Liquid Level Controller?

-

For more than half a century, Warrick controls have provided flexible yet reliable conductive liquid control. They have enabled processes to become automated, offered savings on labour costs and ensured operator safety has remained economical.

- I’m still a little confused – can you help?

-

Of course! If you have a specific query or would simply like some further clarification, please do not hesitate to get in touch with us. A friendly member of our team will talk your requirements through with you and find the right product to suit.

- What types of systems or industries are Warrick Liquid Level controllers used in?

-

All sorts. These liquid level controllers can be used for a wide range of applications, so it really depends on your requirements. We offer many different designs and sensitivity ratings so, if you’re stuck, simply contact us and a member of our team will be able to lend you a helping hand.

Speak to a Friendly Expert Today

If you have any questions about our products or their applications,

please give our friendly team of experts a call.

Our Accreditations